Ongoing projects

Periodic low-dimensional defect structures in polar oxides (FOR5044, coordination project with Mercator module)

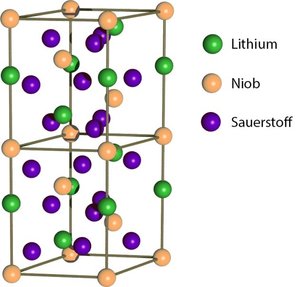

In addition to administrative aspects, the coordination project of the research group includes a Mercator module whose central objective is the elucidation of the electronic equilibrium point defect structure in lithium niobate-lithium tantalate (LNT) solid solutions by means of optical spectroscopy. A special aspect is that the investigations are also carried out under in-situ conditions at high temperatures and defined oxygen partial pressures. In particular, it needs to be clarified whether the three types of polaron identified in lithium niobate (LN) exist stably in Ta-containing solid solutions and especially at higher temperatures. Further focal points are the investigation of chemical diffusion, the nature and temperature dependence of the optical absorption band edge and the dependence of the Fe2+/Fe3+ ratio in Fe-doped LNT on temperature and oxygen partial pressure.

The Mercator module is carried out in close cooperation with Prof. K.-D. Becker (co-head of the research group, University of Braunschweig) and the working groups of Prof. S. Ubizskii and Dr. D. Sugak (Lviv Polytechnic National University, Ukraine).

Furthermore, Prof. G. Borchardt (co-head of the research group, Clausthal University of Technology) actively supports the research work in the field of ion transport, which is located in particular in subproject 2.

Funded by: German Research Foundation

Project partners: www.for5044.de

Contact: Prof. H. Fritze, Ms. T. Kuhfuß (tanja.kuhfuss@tu-clausthal.de)

Ion transport and point defects in LiNb1-xTaxO3 solid solutions (FOR5044, subproject 2)

This subproject focuses on the experimental characterization and fundamental understanding of ion transport and electrical conductivity in lithium niobate-lithium tantalate (LNT) solid solutions with and without ferroelectric domains. In the single crystals, the constituent elements and hydrogen are considered as a function of temperature, oxygen partial pressure and Nb/Ta content. The underlying point defects, defect equilibria and transport mechanisms will be elucidated and the relationship between defect structure and kinetics as well as the influence on the macroscopic material properties will be worked out.

The results of this sub-project contribute significantly to the understanding of partial ionic conductivities and their contribution to the overall conductivity, to the identification of temperature-dependent majority point defects and defect clusters. Specifically, the influence of the paraelectric transition and impurities on diffusion will also be investigated. Of particular importance is the investigation of the influence of the domain walls and the defects/charges associated with them on ion transport.

Funded by: German Research Foundation

Project partners:www.for5044.de

Contact: Prof. H. Fritze, Prof. H. Schmidt (harald.schmidt@tu-clausthal.de)

Thermal stability and application limits of LiNb1-xTaxO3 solid solutions (FOR5044, subproject 3)

This subproject focuses on the influence of Li stoichiometry on the high-temperature stability of the material properties of LNT solid solutions with different Nb/Ta ratios and their application limits. It is known that the two edge components of the Li(Nb,Ta)O3 system - LiNbO3 and LiTaO3 - grow as a congruent system with about 48.4 mol% Li2O. However, the stoichiometric Li/Ta or Li/Nb ratio of 1:1 can be achieved by the VTE process (Vapor Transport Equilibration), for example. LiNbO3 crystals with stoichiometric composition generally show improved electromechanical properties at high temperatures compared to the congruent crystals. However, no data on the influence of Li stoichiometry on the stability of the LNT mixed system is currently available in the literature, but this information is of crucial importance for LNT material properties at high temperatures. Another important focus of the subproject is the behavior and stability of domain walls at high temperatures and the determination of the stoichiometry- and crystal quality-dependent poling properties.

Funded by: German Research Foundation

Project partners:www.for5044.de

Contact person: Dr. Y. Suhak (yuriy.suhak@tu-clausthal.de), S. Hurskyy (stepan.hurskyy@tu-clausthal.de)

Acoustic losses and electromechanical properties of LiNb1-xTaxO3 solid solutions (FOR5044, subproject 7)

Lithium niobate-lithium tantalate (LNT) solid solutions offer both high thermal stability and high piezoelectric coefficients, opening up new, far-reaching application perspectives for piezoelectric structures up to high temperatures. The prerequisite is an understanding of the interaction between point defects and domain walls as well as the effects on the electromechanical properties. The elucidation of directly related phenomena such as acoustic losses is a key focus of this sub-project. In addition to conventional piezoelectric single crystals, it must be taken into account that the loss mechanisms are also determined by the solid solution composition and the domain structure. Provided that the loss mechanisms are understood, both parameters offer numerous possibilities for tailoring the crystal properties. In particular, acoustic losses, the electrical conductivity of domains and domain walls and the coercivity at high temperatures will be determined and correlated with the solid solution composition, the type and density of point defects and the domain wall density and charge, so that atomistic causes such as anelastic relaxations can be assigned. Based on these findings, it will be clarified how acoustic losses can be minimized and whether this can be achieved by doping or a suitable domain structure.

Funded by: German Research Foundation

Project partners:www.for5044.de

Contact: Prof. H. Fritze, Dr. A. Kabir (ansanul.kabir@tu-clausthal.de)

Defect chemistry and electromechanical properties of piezoelectric Ca3TaGa3Si2O14 single crystals at extreme temperatures

Piezoelectric components have a wide range of potential applications even at extreme temperatures. For example, the mass sensitivity of resonant sensors offers advantages in the detection of gases or soot particles and thus supports the increase in efficiency and environmental compatibility of energy conversion processes.

In addition to stability at temperatures up to 1000 °C, for example, low electromechanical losses must be required in all cases. Crystals of the langasite family (La3Ga5SiO14, LGS) are promising piezoelectric materials that can also be used at temperatures above 1300 °C. CTGS (Ca3TaGa3Si2O14) in particular is a langasite isomorph that has an ordered cation structure and low attenuation.

The project aims to investigate the atomic transport and defect chemistry of CTGS in detail, to explain the loss mechanisms and to determine the thermal and chemical application limits of the crystals. Furthermore, a reliable material data set for the piezoelectric, dielectric and elastic constants as well as the conductivity and thermal expansion in the temperature range from 4.2 K to at least 1300 K is to be determined. The stability of the material at high temperatures over a long period of time is another focus of the project.

Funded by: German Research Foundation

Project partner: Leibniz Institute for Solid State and Materials Research Dresden

Contact: Dr. Yuriy Suhak

Growth and characterization of lithium niobate-tantalate solid solutions for sensor and actuator applications in the high-temperature range

Piezoelectric high-temperature actuators, whose deflection can be changed by an applied voltage, are used in the automotive, aerospace and aviation industries, for example. In particular, automotive applications such as internal vibration sensors or active fuel injectors require materials that have high piezoelectric coefficients even at elevated temperatures.

In practice, the application temperature of conventional piezoelectric materials is limited. Polycrystalline ceramics exhibit thermal instability above around 200°C. Crystals of the langasite family (La3Ga5SiO14) are not suitable for actuators due to their low piezoelectric coefficients.

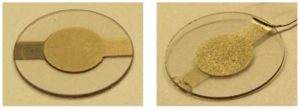

Lithium niobate (LiNbO3) and lithium tantalate (LiTaO3) are potential materials for high-temperature sensors and actuators. Both crystals have high piezoelectric coefficients. However, their use is limited by the thermal instability of LiNbO3 and the low Curie temperature of LiTaO3. Li(Nb,Ta)O3 solid solutions may overcome these limitations of the individual compounds.

The aim of the project is to develop high temperature stable Li(Nb,Ta)O3 solid solutions for sensor and actuator applications. For this purpose, Li(Nb,Ta)O3 single crystals with different Nb/Ta ratios are grown. Furthermore, the defect mechanisms that determine the atomistic transport and the electromechanical properties of Li(Nb,Ta)O3 solid solutions must be investigated and understood.

Funded by: German Research Foundation

Project partner: Institute of Microelectronics Technology and High-Purity Materials, Russian Academy of Sciences

Contact: Dr. Yuriy Suhak

Chemical expansion of praseodymium cerium mixed oxide layers at high temperatures

High-temperature processes are an essential basic element of energy supply and industrial production. Sensors, actuators and sensor-actuator systems that can be used under extreme conditions make it possible to significantly improve these processes in terms of efficiency and environmental compatibility.

Praseodymium-Cerium mixed oxides (PCO) are promising materials for high-temperature actuators, as they achieve significantly greater mechanical deflections than, for example, piezoelectrics suitable for high temperatures. This is due to the chemical expansion and the underlying defect structure, which are to be investigated in more detail as part of the current project. PCO offers decisive advantages compared to other materials:

- High temperature stability

- High chemical expansion

- Customizable material properties by adjusting the Pr/Ce ratio

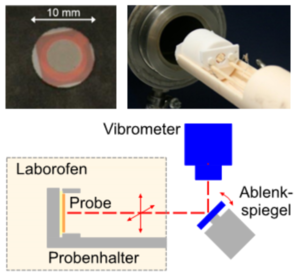

Previously available experimental data on chemical expansion was mainly determined using bulk materials. This project aims to investigate thin films, as they allow the miniaturization of components and short reaction times. To measure the change in thickness of praseodymium-Cer mixed oxide layers, the project partner is further developing an existing high-temperature laser Doppler vibrometer (LDV) in such a way that the measuring range is extended and data is thus accessible over a wide temperature range.

At 800 °C and an excitation voltage of only 0.7 V, deflections of more than 100 nm have already been demonstrated for a composite consisting of a 2 µm thick PCO layer on a zirconium oxide substrate.

Funded by: German Research Foundation

Project partner: Clausthal University of Technology, Institute for Electrical Information Technology

Cooperation partner: Massachusetts Institute of Technology, Department of Materials Science and Engineering

Contact: Dr. Hendrik Wulfmeier

Epitaxial deposition of oxide piezoelectric layers

Piezoelectric single crystals are widely used sensor and actuator materials for the high-temperature range, e.g. as gravimetric or calorimetric sensors. As such, they are important components for process control and for monitoring energy conversions and material transport.

Materials of the langasite family (La3Ga5SiO14, LGS) allow operating temperatures of well over 1000 °C in both oxidizing and reducing atmospheres. However, the applicability of these components above 1000 °C is limited by the stability of the electrode materials required for piezoelectric excitation. Thin layers of platinum or platinum alloys are the current state of research here, but these exhibit degradation effects such as oxidation, evaporation and agglomeration in the temperature range mentioned.

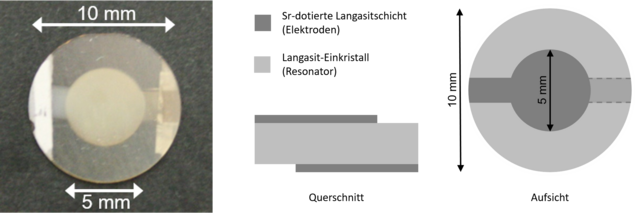

Monolithic electrodes made of oxides with adapted thermal expansion are promising alternatives for improving long-term stability. In order to function as electrodes, their conductivity must be significantly higher than that of the resonator crystal. In the project, this is achieved by depositing doped langasite layers. La is partially replaced by Sr. The increased oxygen vacancy concentration leads to an increase in the layer conductivity.

The main focus of this project is on the development of an epitaxial growth process for these layers. The main challenge here is to adjust phase and stoichiometry in parallel.

Another motivation for the epitaxial deposition of thin oxide layers is the miniaturization of sensor and actuator components for high-temperature applications under oxidizing atmospheres. Here, not only homoepitaxial (LGS on LGS) but also heteroepitaxial layers (LGS on Si, SiO2,...) are of interest.

Funded by: German Research Foundation

Contact: Dr. Hendrik Wulfmeier

EML OCS - Oxygen Control System

The electromagnetic levitator (EML) is a system installed on the International Space Station (ISS) that allows the contactless examination of high-purity materials under microgravity near and well above the melting temperature. Conductive samples such as alloys are positioned and melted using high-frequency magnetic fields. The process is used to obtain information about surface tension, viscosity and/or conductivity. Although electromagnetic levitation is a non-contact method, thin oxide layers on the sample surface or oxygen dissolved in the sample can strongly influence the measurement results. Therefore, precise knowledge of the oxygen content in the atmosphere and the ability to influence this is the basic prerequisite for reproducible and reliable measurements.

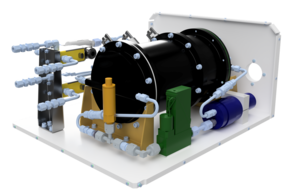

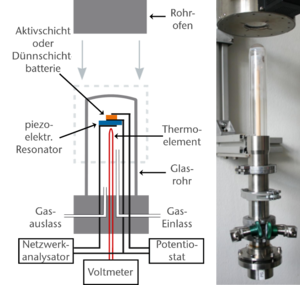

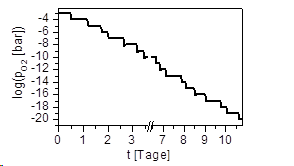

The aim of this project is to develop and test a system based on the solid electrolyte YSZ (yttrium-stabilized zirconium oxide) for measuring and controlling the oxygen partial pressure. The system enables the measurement of the oxygen partial pressure in the range from 10-3 to 10-26 bar with an accuracy of log(pO2/bar) < 0.02 at the sensor location. The control allows bidirectional pumping of up to approx. 800 mm3 O2 per hour with a resolution of 0.001 mm3/min and an adjustment of the oxygen partial pressure in the range of 10-20 to 10-3 bar. The system works autonomously. Parameters such as gas flow rate, oxygen partial pressure and valve settings (gas circulation with/without oxygen pump) are specified by the ISS ground station prior to the corresponding experiments.

Funded by: European Space Agency ESA (contract 21788/08/NL/BJ, CCN38:EML Oxygen sensing and Control System Phase B Development, completed in February 2019)

Project partners: Airbus DS (Friedrichshafen, Germany)

DTM Technologies (Modena, Italy)

Kayser Italia (Livorno, Italy)

Contact: Dr. Michal Schulz

Determination of the evaporation rate of Ag and Ag-Cu in zero gravity

The investigation of high-purity metals and alloys requires measurement conditions that are as free of interference as possible. Contactless melting and virtually force-free environments are essential aspects of this. These conditions are met by the electromagnetic levitator (EML), which is located on the International Space Station (ISS). The surface tension and electrical conductivity of various melts, for example, can currently be determined there.

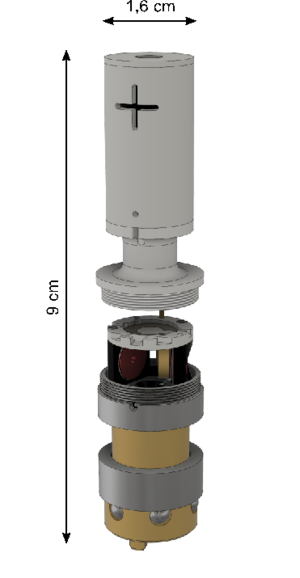

The aim of the project is to develop a miniaturized system for the high-precision determination of the vapour pressure and thus the free Gibbs enthalpy of technologically relevant metals and alloys by measuring the evaporation rates. The measuring principle is based on a resonant nanobalance made of a high-temperature stable quartz isotope, which can be piezoelectrically excited up to a melting temperature of 1473°C. The molecular beam from the Knudsen cells is deposited on the surface of the resonator, whereby this mass deposition leads to a measurable shift in the resonant frequency.

The system is to be tested during the DLR parabolic flight campaigns in 2019 and 2020. It will be integrated into DLR's TEMPUS facility (crucible-free electromagnetic processing under zero gravity). Ag and Ag60Cu40 samples will be melted without contact and examined with the system. The results will be compared with literature values and with the numerical models developed by the project partner.

Funded by: Federal Ministry for Economic Affairs and Energy

Project partner: Mannheim University of Applied Sciences

Contact: Dr. Michal Schulz

Electromechanical properties and atomic transport in AlN bulk crystals at high temperatures

The excellent electromechanical properties as well as the chemical and thermal stability of aluminum nitride (AlN) offer great potential for use as piezoelectric resonators at high temperatures.

Due to the limited availability of AlN bulk crystals of sufficient size and quality, reliable material data for AlN are not yet available. In cooperation with the Leibniz Institute for Crystal Growth (IKZ) in Berlin, AlN volume crystals are to be grown and the electromechanical properties, defect chemistry and atomic transport processes up to temperatures of 1300 °C are to be investigated. Degradation effects in oxidizing atmospheres and dependencies on crystal quality, crystal orientation, growth conditions and defects will also be taken into account. With the aim of implementing AlN bulk crystals in high-temperature applications, technological limits for their use as sensor and/or actuator materials will be determined. In this context, the electromechanical properties are investigated and modelled, particularly with regard to the loss mechanisms, in order to minimize these and extend the application limits.

Funded by: German Research Foundation

Project partner: Leibniz Institute for Crystal Growth

Project partner: Dr. Iurii Kogut

In situ method for the determination of high oxygen deficits in cerium-zirconium mixed oxides for exhaust gas aftertreatment

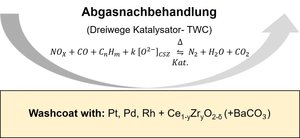

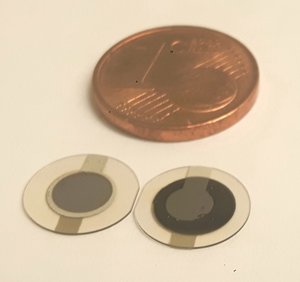

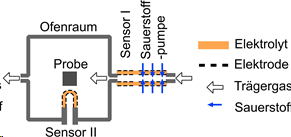

Cerium-zirconium mixed oxides (Ce1-yZryO2-x) are part of the catalyst carrier (washcoat) in automotive catalytic converters and are used to minimize harmful combustion products such as nitrogen oxides. The aim of the project is to develop a fundamental understanding of the defect chemistry of cerium-zirconium mixed oxides (Ce1-yZryO2-x) and their influence on the application for exhaust gas aftertreatment in so-called three-way catalytic converters (TWCs). Due to the reversible release and absorption of oxygen in pure cerium-zirconium mixed oxides (Ce1-yZryO2-x), targeted exhaust gas aftertreatment of gasoline-powered automobiles can be carried out depending on the temperature and oxygen partial pressure. At very high oxygen deficits, pure cerium oxide (CeO2) has a high chemical expansion, which is reduced by targeted doping with ZrO2 and additionally improves the catalyst stability in the process. Two complementary in-situ measurement methods are used to develop basic models to describe the non-stoichiometry of cerium-zirconium mixed oxides (Ce1-yZryO2-x): 1) Nanobalance using high-temperature stable piezoelectric resonators 2) Microwave characterization in a cavity resonator

Funded by: German Research Foundation

Project partner: Chair of Functional Materials, University of Bayreuth

Contact: Alexander Wollbrink

Concentration-dependent industrial furnace control

The aim of the joint project is to develop a sensor technology that allows precise and therefore energy-efficient control of electrically heated heat treatment processes. The control is based on the measurement of changes in the concentration of one or more key gas species, which allow direct conclusions to be drawn about the condition of the components in the system.

For gas detection, gravimetric and electrical changes in the properties of metal oxide sensor layers are measured using a high-temperature stable resonant microbalance. Piezoelectric Ca3TaGa3Si2O14 (CTGS) single crystals are used as resonator material, which are coated with electrodes and excited to volume oscillations. (Pr,Ce)O2, SnO2 and TiO2 sensor layers are applied to the electrodes. The additional measurement of gravimetric effects of the sensor layers leads to a gain in information, through which the selectivity can be increased compared to conventional metal oxide gas sensors. The materials used allow gas detection even in highly reducing atmospheres at temperatures up to at least 1000 °C.

The simultaneous characterization of gravimetric properties of a Pr0.1Ce0.9O2 sensor layer and electrical properties of SnO2 and TiO2 sensor layers enable, for example, the differentiation of methane (CH4) and ethene (C2H4) at temperatures of 350 °C to 450 °C

Funded by: Federal Ministry for Economic Affairs and Energy

Project partners:Fraunhofer Institute for Manufacturing Technology and Advanced Materials, SGL Group, Element 22, MUT Advanced Heating

Contact: Sebastian Schröder

Completed projects

Correlation of model and commercial active materials for lithium-ion batteries by means of in-situ determination of thermodynamic and kinetic data

(Sub-project within the framework of the priority program "Materials with new design for lithium-ion batteries" (WeNDeLIB))

The main objectives of the project include the determination of thermodynamic data and the elucidation of transport kinetics and transport paths in selected electrode materials for lithium-ion batteries. Calorimetry on thin films has been the subject of research for several decades, as the thermodynamic properties of thin films can often differ considerably from bulk crystals. The limiting factor in previous approaches was the maximum operating temperature of just over 500 °C.

The new high-temperature thin-film calorimeter (TFC) developed at the TUC combines the aspects of "calorimetry on thin films" and "high-temperature physics" for the first time. Measurements at temperatures up to 1100 °C are realized on single layers and layer systems (100 nm to several µm). The core components of the TFC are high-temperature stable piezoelectric langasite resonators (La3Ga5SiO14, LGS), whose resonance frequency shows a high temperature dependence. They are used as high-precision planar temperature sensors. Deviations from the undisturbed temperature dependence of the resonant frequency characterize calorimetric effects in the layers to be investigated and are converted into the corresponding enthalpies. The resolution is 1.9 mJ. Structured and miniaturized resonators are used to further improve sensitivity.

A variety of battery materials were investigated:

(1) Electrodes: Li(Ni,MnCo,Al)xOy, LixCy, Sn, LiFe1-x(Al/Ni)xPO4, MoS2

(2) Solid electrolytes: SPEEK, LVSO, LiPON

In thin LiMn2O4 layers, for example, strong dependencies of (re-)crystallization on the atmosphere were found. Furthermore, TFC was used to document the heat development of a solid-state thin-film battery in-situ during several charging cycles for the first time.

Funded by: German Research Foundation, SPP 1473

Project partner: TU Ilmenau, Interfaculty Institute for Materials Engineering

Contact: Dr. Hendrik Wulfmeier

Defect chemistry and electromechanical properties of stoichiometric lithium niobate at temperatures up to at least 900 °C

Defect chemistry and electromechanical properties of stoichiometric lithium niobate at temperatures up to at least 900 °C

Funded by: DFG

Project partners: Prof. G. Borchardt (TU Clausthal)

Prof. K.-D. Becker (TU Braunschweig)

Sensor Materials and Device Structures for High-Temperature Piezoelectric Transducers

Concepts for new piezoelectric transducer structures are being designed as part of the personnel exchange program. The project includes preliminary investigations that will lead to further cooperation.

Funded by: DFG

Project partner: Prof. H. L. Tuller (Massachusetts Institute of Technology, Cambridge, USA)

SAWHOT - Surface Acoustic Wave Wireless Sensors for High Operating Temperatures

The aim of the project is to develop a high-temperature system for wireless measurement of physical parameters. Material science challenges include the creation of high temperature capable langasite surface wave elements. The applicant's sub-project includes the production and testing of Pt, Rh, Ir and ceramic electrode structures. Of particular interest are the conductivity and reactions with the langasite substrate. The latter will be investigated using mass- and isotope-selective analysis, i.e. SIMS, as this allows the reaction sources to be identified.

Funding: EU and Russia

Project partners: 9 EU partners and 4 Russian partners

Oxygen Sensing and Control

The aim of the study is to evaluate several approaches for measuring and adjusting the oxygen partial pressure during material investigations in space. In the short term, relatively high (pO2 > 10-7 bar) and in the long term very low (pO2 > 10 22 bar) oxygen partial pressures are to be specified for levitation melting experiments. Potentiometric sensors and controlled oxygen pumps from the applicant's working group were selected for the further course of the project so that corresponding technology demonstrators can be set up and tested.

Funded by: EADS/Astrium

Project partners: Prof. S. Fasoulas (University of Stuttgart)

Prof. J. Wöllenstein (Fraunhofer Institute for Physical Measurement Techniques, Freiburg)

Interfacial oxygen transport in metal oxide superlattices

Cooperation project with Technion (Israel) funded by the state of Lower Saxony

The aim of this project is to produce nanostructured ceramics with very high ionic conductivity. Material combinations such as SrTiO3 and SrTi1-xFexO3 are tailored by selecting defined layer sequences in the range of a few tens of nanometers. This innovative approach leads to space charges and thus to the targeted adjustment of the defect chemistry and the potentials at the interfaces. The corresponding electric fields promote the transfer of oxygen, for example, between the individual layers, which leads to the desired increase in ionic conductivity in fuel cells

GEENI - Graduate School Energy Storage and Electromobility Lower Saxony

Graduate school on lithium-ion batteries funded by the state of Lower Saxony.

The aim of the research program is to clarify the mutual dependencies of the transport processes (ion, electron and heat flow) and the mechanical stress on the materials used and the manufacturing processes in order to achieve substantial improvements in battery systems for electromobility using new materials and manufacturing technologies. The research programme is structured along the size scale from micro (molecule to particle level) to meso (electrode level) to macro (cell or system level) and along methodological aspects (preparation, characterization at material and cell level and simulation).